Laser guided machines‚ enhanced by machine learning‚ are revolutionizing automation‚ offering precision and adaptability.

These systems leverage algorithms for improved data analysis and control‚

particularly in complex tasks like surgical procedures and robotic navigation.

Overview of the Integration

The integration of machine learning (ML) into laser guided machines represents a significant leap in automation and control systems. Historically‚ laser guidance relied on pre-programmed instructions and limited feedback mechanisms. However‚ incorporating ML allows these machines to learn from data‚ adapt to changing environments‚ and improve performance over time.

Self-supervised learning is pivotal‚ enabling robots to generate training data‚ interpreting ambiguous sensor information – crucial for navigating rough terrain or identifying objects like dust and snow. Systems like Watch-Bot‚ utilizing 3D sensors and laser pointers‚ demonstrate this capability by learning and recognizing normal human activity through probabilistic methods.

Furthermore‚ advancements in areas like LASIK surgery‚ with technologies like Custom Eyes‚ showcase ML’s ability to process vast datasets (over 100‚000 corneal points) for personalized and precise corrections. This synergistic blend of laser technology and machine learning is driving innovation across diverse fields.

Historical Context of Laser Guidance

Early laser guidance systems‚ emerging in the mid-20th century‚ were primarily employed in military applications‚ focusing on missile guidance and target designation. These initial systems relied on simple triangulation and beam steering‚ offering a substantial improvement over previous methods but lacked adaptability. The core principle involved directing a laser beam onto a target and utilizing the reflected light for precise tracking and control.

Over time‚ advancements in laser technology led to increased accuracy and range. However‚ these systems remained largely dependent on pre-defined parameters and struggled with dynamic environments or obscured targets. The introduction of digital signal processing offered incremental improvements‚ but a fundamental shift was needed.

The recent integration of machine learning marks a paradigm shift‚ moving beyond pre-programmed responses to systems capable of learning and adapting. This evolution builds upon decades of laser guidance development‚ now augmented by the power of data-driven intelligence.

The Role of Machine Learning in Modern Laser Systems

Machine learning fundamentally transforms laser guidance‚ enabling systems to overcome limitations of traditional approaches. Self-supervised learning allows robots to generate training data‚ interpreting ambiguous sensor information – crucial for navigating complex terrains or identifying objects like dust or snow; Algorithms analyze data from cameras and sensors‚ enhancing object detection and 3D scene modeling.

This integration isn’t about creating “true AI‚” but leveraging data analysis and automated controls to improve precision. For example‚ LASIK procedures now utilize machine learning to map corneal points with exceptional accuracy‚ tailoring laser corrections to individual optical fingerprints.

Furthermore‚ machine learning facilitates human-AI co-design‚ exemplified by PCSEL optimization‚ minimizing human intervention while maximizing design efficiency. It’s a move towards adaptive‚ intelligent laser systems.

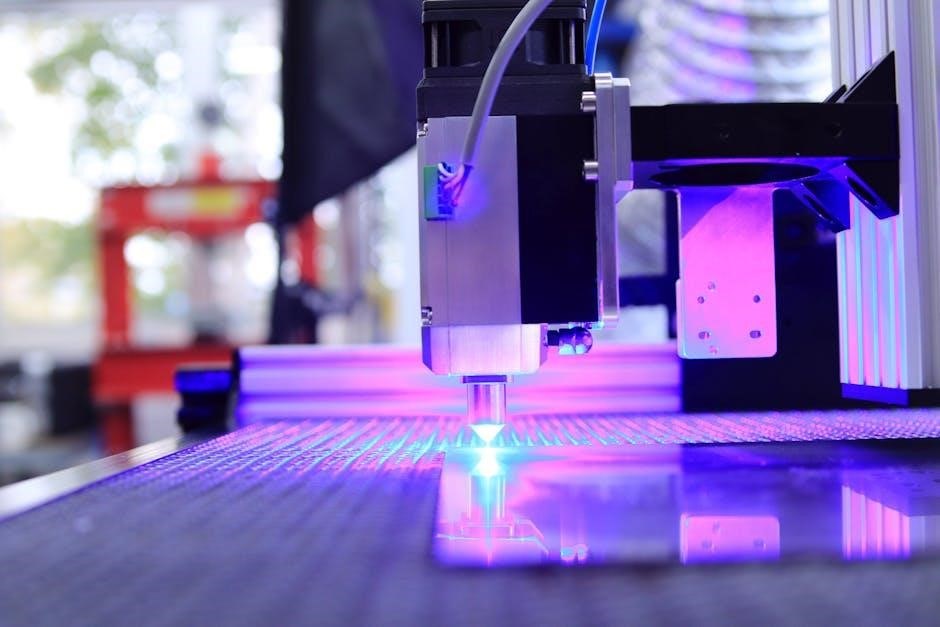

Core Components of a Laser Guided Machine

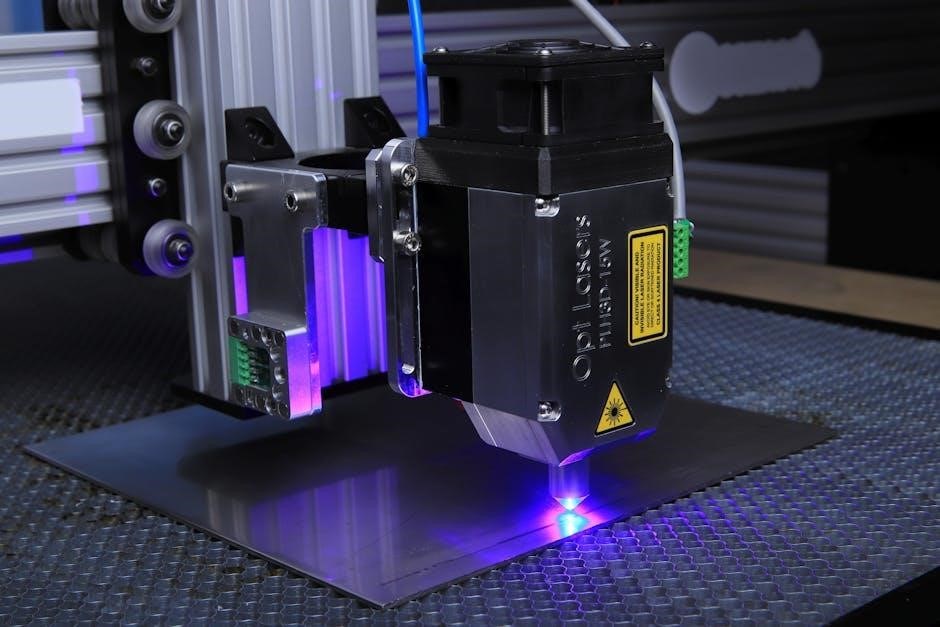

Essential components include laser systems‚ machine vision (cameras & sensors)‚ and processing units – hardware and software – working in synergy for precise‚ automated control.

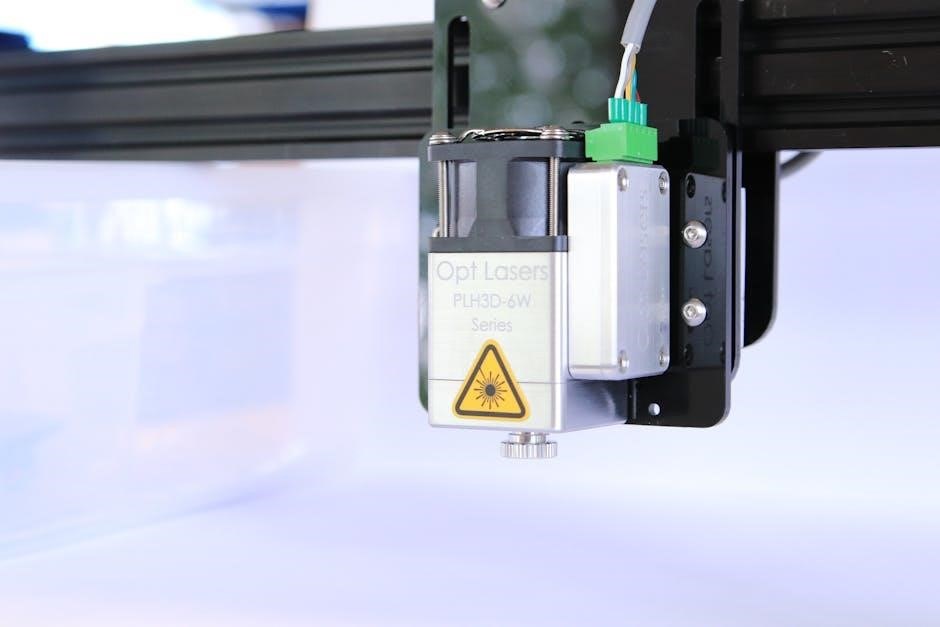

Laser Systems: Types and Specifications

Various laser types underpin guided machine functionality‚ each with unique specifications. PCSELs (Photonic Crystal Surface Emitting Lasers) are emerging‚ benefiting from LLM-driven design optimization for enhanced performance. Traditional lasers‚ however‚ remain prevalent‚ categorized by wavelength‚ power output‚ and beam quality. CO2 lasers are common in industrial cutting‚ while Nd:YAG lasers find use in marking and engraving.

Specifications are critical; wavelength dictates material interaction‚ power determines processing speed‚ and beam quality impacts precision. Laser systems must integrate seamlessly with machine vision and control systems. Mirror positional adjustment and optimal parameter selection are crucial for accuracy. The choice of laser directly influences the machine’s capabilities and suitability for specific applications‚ ranging from delicate surgical procedures to robust industrial automation tasks.

Machine Vision Systems: Cameras and Sensors

Machine vision is integral to laser guided machines‚ providing the ‘eyes’ for precise operation. Systems commonly employ 3D sensors‚ like the Kinect used in the Watch-Bot project‚ capturing depth information for scene understanding. Standard cameras‚ alongside specialized topography sensors‚ gather detailed visual data. Custom Eyes with Foresight technology utilizes detailed corneal mapping‚ processing over 100‚000 points for LASIK procedures.

Sensor specifications are paramount; resolution dictates detail capture‚ frame rate impacts real-time responsiveness‚ and sensitivity determines performance in varying lighting conditions. Data from these sensors feeds into machine learning algorithms for object recognition‚ obstacle avoidance‚ and accurate positioning. Robustness to environmental factors‚ like dust and snow‚ is a key design consideration‚ enabling reliable performance in challenging conditions.

Processing Units: Hardware and Software

The brain of a laser guided machine resides in its processing unit‚ encompassing both hardware and software components. Watch-Bot‚ for example‚ utilizes a laptop to process data from its 3D sensor and camera. Advanced software‚ crucial for Custom Eyes’ LASIK technology‚ analyzes detailed corneal topography and wavefront data.

Hardware often includes GPUs for accelerated machine learning computations‚ alongside CPUs for general-purpose processing. Software leverages algorithms – supervised‚ unsupervised‚ and reinforcement learning – to interpret sensor data and control laser parameters. LLMs are emerging tools‚ demonstrated in PCSEL design optimization‚ minimizing human intervention. Real-time processing capabilities are vital‚ demanding efficient algorithms and powerful hardware to ensure responsive and accurate machine operation.

Machine Learning Algorithms for Laser Guidance

Supervised‚ unsupervised‚ and reinforcement learning algorithms empower laser guided machines with adaptive control‚ enabling precise adjustments and optimized performance in diverse applications.

Supervised Learning Techniques

Supervised learning forms a cornerstone of modern laser guidance systems‚ utilizing labeled datasets to train algorithms for specific tasks. These techniques excel in scenarios where clear input-output relationships are defined‚ such as object recognition and precise positional adjustments. For instance‚ in LASIK surgery‚ detailed corneal topography and wavefront data – the labeled input – are used to train models that predict optimal laser parameters for vision correction‚ achieving exceptional accuracy based on each eye’s unique characteristics.

Algorithms like support vector machines (SVMs) and neural networks are frequently employed to classify objects or predict continuous values. In industrial automation‚ supervised learning can be used to identify defects on a production line‚ guiding the laser to selectively remove flawed components. The success of these techniques hinges on the quality and quantity of the training data‚ demanding careful data acquisition and preprocessing to ensure robust and reliable performance. This approach allows for highly accurate and repeatable results‚ crucial for applications demanding precision.

Unsupervised Learning Applications

Unsupervised learning techniques offer valuable capabilities for laser guided machines‚ particularly in scenarios lacking labeled training data. These methods excel at discovering hidden patterns and structures within complex datasets‚ enabling adaptive behavior and improved performance in dynamic environments. Self-supervised learning‚ a prominent example‚ allows robots to generate their own training examples‚ interpreting ambiguous sensor data – like distinguishing dust from obstacles – without explicit human labeling.

Applications include 3D-scene analysis and modeling vehicle dynamics‚ enhancing robotic navigation in rough terrain. Clustering algorithms can identify common features in sensor data‚ allowing the machine to categorize objects or environments without prior knowledge. This is particularly useful for anomaly detection‚ identifying unexpected events or deviations from normal operation. By autonomously learning from data‚ these systems demonstrate increased robustness and adaptability‚ reducing reliance on pre-programmed instructions and improving overall efficiency.

Reinforcement Learning for Adaptive Control

Reinforcement learning (RL) provides a powerful framework for adaptive control in laser guided machines‚ enabling them to learn optimal strategies through trial and error. Unlike supervised learning‚ RL doesn’t require labeled data; instead‚ the machine learns by receiving rewards or penalties for its actions within a defined environment. This is particularly valuable for tasks where optimal control parameters are unknown or constantly changing.

RL algorithms can optimize laser parameters‚ mirror positioning‚ and other control variables to maximize performance metrics like accuracy or efficiency. This approach is especially beneficial in complex scenarios‚ such as navigating unpredictable terrain or adapting to varying environmental conditions. The iterative learning process allows the machine to refine its control strategies over time‚ leading to improved robustness and precision. Furthermore‚ RL facilitates embodied robotic AI tasks‚ allowing machines to learn complex behaviors through interaction with the physical world‚ enhancing their overall autonomy and adaptability.

Applications of Laser Guided Machines

Laser guided machines with machine learning are transforming industries‚ from precise surgical procedures like LASIK to advanced industrial automation and robust defense systems.

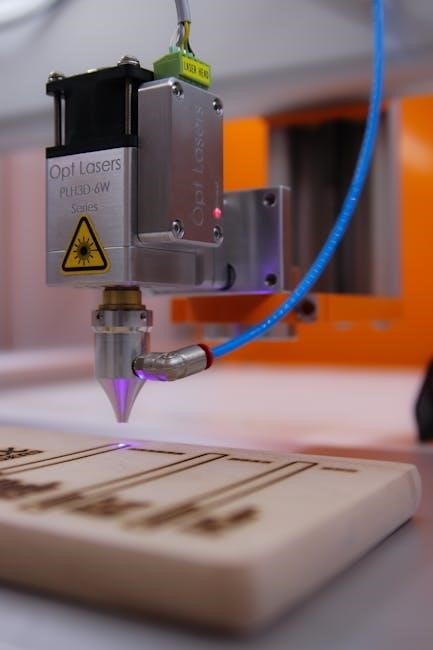

Industrial Automation and Robotics

Machine learning significantly enhances laser guided machines in industrial settings‚ enabling sophisticated automation and robotic applications. These systems excel at tasks requiring high precision and adaptability‚ such as object detection and rejection – differentiating between desired products and imperfections like dust or snow. They’re also crucial for navigating rough terrain‚ identifying obstacles‚ and performing detailed 3D-scene analysis.

The integration of self-supervised learning allows robots to generate their own training data‚ improving performance by interpreting ambiguous sensor information with a priori knowledge. This is particularly valuable in complex environments where pre-programmed instructions are insufficient. Watch-Bot‚ developed by Cornell and Stanford researchers‚ exemplifies this‚ utilizing a laser pointer and 3D sensor to learn and detect normal human activity patterns through probabilistic methods. This technology boosts efficiency and reduces human error in manufacturing and logistics.

Medical Applications: LASIK and Surgery

Laser guided machines‚ coupled with machine learning‚ are transforming medical procedures‚ particularly in fields like ophthalmology and surgery. AI-assisted LASIK‚ such as Custom Eyes with Foresight technology‚ utilizes detailed corneal mapping – analyzing over 100‚000 points – to create a unique optical fingerprint for each patient. Advanced software then processes this data‚ guiding the laser for exceptionally accurate vision correction.

While not strictly “true AI‚” these systems employ algorithm-driven data analysis and automated controls to significantly enhance surgical outcomes. Machine learning algorithms improve precision‚ reduce invasiveness‚ and personalize treatment plans; This technology extends beyond LASIK‚ aiding in other surgical applications where precise targeting and real-time adjustments are critical. The ability to analyze complex data and adapt to individual patient needs represents a major advancement in medical technology‚ improving patient safety and recovery times;

Defense and Security Systems

Laser guided machines‚ integrated with machine learning‚ are increasingly vital in modern defense and security applications. These systems offer enhanced capabilities in threat detection‚ target recognition‚ and precision engagement. Machine learning algorithms enable these machines to differentiate between legitimate targets and innocuous objects – effectively rejecting elements like dust or snow – crucial for reliable operation in challenging environments.

Furthermore‚ these technologies support advanced surveillance and perimeter security‚ identifying potential obstacles and human activity with greater accuracy. Systems like Watch-Bot‚ utilizing 3D sensors and laser pointers‚ demonstrate the potential for automated detection of normal and anomalous behaviors. The ability to analyze complex scenarios and adapt to evolving threats makes laser guided machines with machine learning a cornerstone of future defense strategies‚ improving response times and minimizing risks.

Data Acquisition and Preprocessing

Effective laser guidance relies on robust data collection‚ cleaning‚ and feature extraction from sensors; data augmentation improves machine learning model performance significantly.

Sensor Data Collection Methods

Diverse sensor technologies are crucial for acquiring the necessary data to power laser-guided machines with machine learning capabilities. 3D sensors‚ like the Kinect utilized in the Watch-Bot project‚ provide depth information essential for scene understanding and object recognition. Complementary camera systems capture visual data‚ enabling the identification of objects and terrain features – distinguishing between obstacles like dust‚ snow‚ or even vegetables.

Furthermore‚ detailed topography and wavefront data‚ as employed in Custom Eyes’ Foresight technology for LASIK‚ demonstrate the power of high-resolution optical sensors. These sensors map corneal points with exceptional accuracy‚ providing a unique optical fingerprint for each eye. The collection isn’t limited to passive observation; laser pointers themselves can actively contribute to data acquisition‚ aiding in the creation of 3D models and dynamic scene analysis. The integration of these varied data streams is fundamental to achieving robust and reliable performance in laser-guided systems.

Data Cleaning and Feature Extraction

Raw sensor data from laser-guided machines often contains noise and inconsistencies‚ necessitating robust cleaning procedures. This involves filtering out erroneous readings‚ handling missing values‚ and correcting for sensor biases. Crucially‚ data augmentation techniques can expand the training dataset‚ improving the machine learning model’s generalization ability‚ particularly when dealing with limited real-world examples.

Following cleaning‚ feature extraction becomes paramount. This process identifies and isolates the most relevant information from the data‚ transforming it into a format suitable for machine learning algorithms. For instance‚ in the Watch-Bot system‚ probabilistic methods are used to learn patterns of normal human activity. Similarly‚ Custom Eyes extracts features from corneal topography to create a unique optical fingerprint. Effective feature extraction significantly impacts the accuracy and efficiency of the laser guidance system.

Data Augmentation Techniques

Data augmentation is critical for enhancing the performance of machine learning models in laser-guided machines‚ especially when real-world data is scarce. Techniques include introducing slight variations to existing data – rotating‚ scaling‚ or adding noise to images captured by machine vision systems. Self-supervised learning approaches‚ as seen in robotic applications‚ generate training examples autonomously‚ effectively augmenting the dataset.

This is particularly useful for interpreting ambiguous sensor data‚ like distinguishing between dust and actual obstacles. By creating synthetic data that mimics diverse environmental conditions‚ the system becomes more robust. For example‚ augmenting data with varying lighting conditions improves performance in outdoor applications. Ultimately‚ these techniques improve the model’s ability to generalize and perform reliably in real-world scenarios‚ mirroring the adaptability demonstrated by embodied robotic AI.

Challenges and Future Directions

Real-time processing and environmental robustness remain key challenges‚ alongside ethical considerations and safety protocols for laser guided machines utilizing machine learning.

Real-time Processing Constraints

Achieving real-time performance is a significant hurdle for laser guided machines employing machine learning. The necessity for immediate responses in dynamic environments‚ such as industrial robotics or surgical applications‚ demands exceptionally fast processing speeds. Complex machine learning algorithms‚ while powerful‚ can be computationally intensive‚ creating latency issues.

This constraint necessitates optimized algorithms and powerful processing hardware. Efficient data preprocessing‚ feature extraction‚ and model inference are crucial. Furthermore‚ the integration of edge computing – processing data closer to the source – can mitigate delays associated with data transmission.

Balancing algorithmic complexity with processing speed remains a core challenge‚ requiring innovative approaches to algorithm design and hardware acceleration to ensure responsiveness and reliability in real-world applications. The demand for instantaneous decision-making is paramount.

Robustness to Environmental Factors

Laser guided machines operating in real-world scenarios face considerable challenges from fluctuating environmental conditions. Factors like dust‚ snow‚ varying lighting‚ and rough terrain can significantly degrade sensor data and compromise system performance. Machine learning models trained on pristine datasets often struggle to generalize effectively when confronted with such real-world noise and ambiguity.

Developing robust systems requires incorporating techniques like data augmentation – artificially expanding the training dataset with simulated environmental variations – and employing algorithms resilient to outliers and noisy inputs. Self-supervised learning‚ enabling robots to learn from unlabeled data‚ proves valuable in adapting to unforeseen conditions.

Furthermore‚ sensor fusion – combining data from multiple sensors – can enhance reliability and provide redundancy‚ mitigating the impact of individual sensor failures or limitations. Ensuring consistent performance across diverse environments is critical for widespread adoption.

Ethical Considerations and Safety Protocols

The increasing autonomy of laser guided machines powered by machine learning necessitates careful consideration of ethical implications and robust safety protocols. As these systems become more prevalent in sensitive applications like surgery and defense‚ ensuring responsible development and deployment is paramount.

Potential biases in training data can lead to discriminatory or unintended consequences‚ demanding rigorous data validation and fairness assessments. Transparency in algorithmic decision-making is crucial for accountability and building public trust. Safety protocols must prioritize human oversight and incorporate fail-safe mechanisms to prevent harm.

Furthermore‚ addressing potential job displacement due to automation and establishing clear guidelines for liability in case of system malfunctions are essential ethical considerations. A proactive‚ multi-stakeholder approach is vital for navigating these complex challenges.

Specific Examples and Case Studies

Watch-Bot‚ Custom Eyes‚ and PCSEL design optimization demonstrate machine learning’s impact. These examples showcase advancements in human activity detection‚ LASIK‚ and laser methodologies.

Watch-Bot: Human Activity Detection

Watch-Bot‚ developed by Cornell and Stanford researchers‚ exemplifies a practical application of laser-guided systems coupled with machine learning for nuanced environmental understanding. This innovative system utilizes a combination of readily available components – a 3D sensor (Kinect)‚ a standard camera‚ a laptop‚ and a laser pointer – to achieve robust human activity detection.

The core functionality of Watch-Bot relies on its ability to learn patterns of “normal” human activity through probabilistic methods. This learning process allows it to differentiate between expected movements and anomalies‚ effectively monitoring spaces for unusual behavior. Crucially‚ Watch-Bot demonstrates the power of self-supervised learning‚ generating its own training examples to refine performance. This is particularly valuable when interpreting ambiguous sensor data‚ leveraging a priori knowledge and close-range data to understand long-range observations. The system’s ability to detect and reject interference‚ like dust or snow‚ further highlights its robustness.

Custom Eyes with Foresight Technology

Custom Eyes represents a significant advancement in AI-assisted LASIK surgery‚ showcasing the precision achievable through machine learning integration with laser guidance systems. This technology moves beyond traditional methods by employing detailed corneal topography and wavefront data‚ meticulously mapping over 100‚000 unique points on each eye.

The collected data isn’t merely visualized; it’s processed by sophisticated software algorithms that create a personalized “optical fingerprint” for each patient. This fingerprint then guides the laser during the corrective procedure‚ ensuring unparalleled accuracy tailored to the individual’s specific needs. While not strictly “true AI” in the broader machine learning sense‚ Custom Eyes leverages algorithm-driven data analysis and automated controls to dramatically enhance surgical outcomes‚ minimizing invasiveness and maximizing visual acuity. This exemplifies how machine learning refines laser precision for improved patient care.

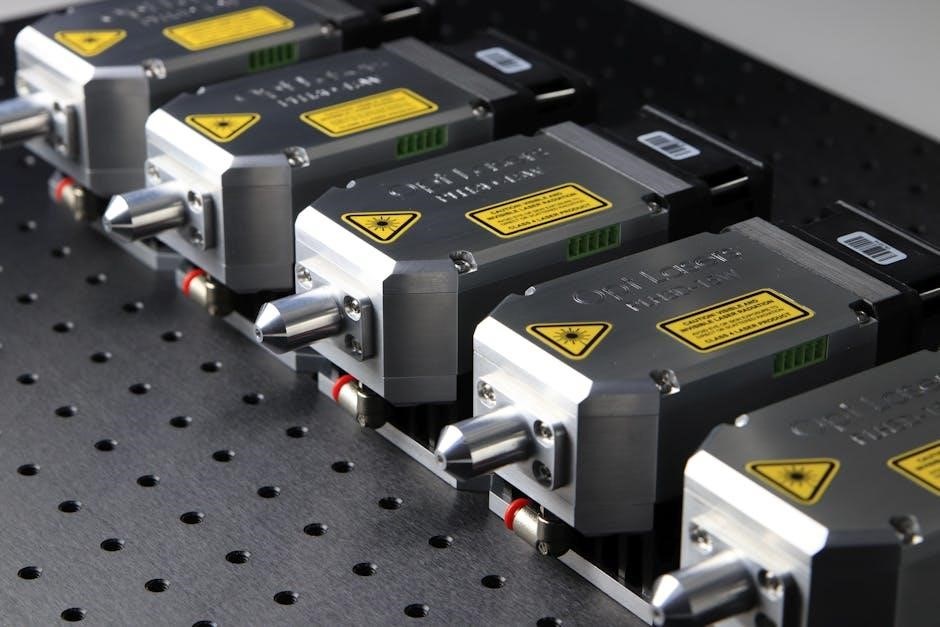

PCSEL Design Optimization with LLMs

Recent research explores a novel human-AI co-design paradigm for Photonic Crystal Surface Emitting Lasers (PCSELs)‚ leveraging the power of Large Language Models (LLMs) to streamline the design process. This approach aims to minimize human intervention while maximizing optimization potential‚ demonstrating practical implications for laser design methodologies.

Researchers are actively verifying the application of LLMs to machine learning-based PCSEL design and optimization. The core principle involves utilizing LLMs to analyze complex design parameters and predict optimal configurations‚ reducing the need for extensive manual experimentation. This work builds upon advancements in embodied robotic AI and seeks to automate critical steps in optical component control‚ including mirror positional adjustment and laser parameter selection. The goal is a more efficient and precise laser design workflow‚ driven by intelligent automation.